Page 46 - Annual Report_21-22

P. 46

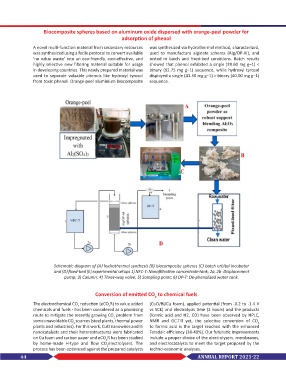

Biocomposite spheres based on aluminum oxide dispersed with orange-peel powder for

adsorption of phenol

A novel multi-function material from secondary resources was synthesized via hydrothermal method, characterized,

was synthesized using a facile protocol to convert available used to manufacture alginate spheres (Alg/OP-Al), and

‘no value waste’ into an eco-friendly, cost-effective, and tested in batch and fixed-bed conditions. Batch results

highly selective new filtering material suitable for usage showed that phenol exhibited a single (39.60 mg g−1) <

in developing countries. This newly prepared material was binary (92.75 mg g−1) sequence, while hydroxyl tyrosol

used to separate valuable phenols like hydroxyl tyrosol displayed a single (41.50 mg g−1) > binary (40.00 mg g−1)

from toxic phenol. Orange-peel aluminium biocomposite sequence.

Schematic diagram of (A) hydrothermal synthesis (B) biocomposite spheres (C) batch orbital incubator

and (D) fixed-bed (E) experimental setups 1) NFC-T: Nanofiltration concentrate tank; 2a, 2b- Displacement

pump; 3) Column; 4) Three-way valve; 5) Sampling point; 6) DP-T: De-phenolized water tank.

Conversion of emitted CO to chemical fuels

2

The electrochemical CO reduction (eCO R) to value added (CuO/Bi/Cu foam), applied potential (from -0.2 to -1.4 V

2

2

chemicals and fuels - has been considered as a promising vs SCE) and electrolysis time (2 hours) and the products

route to mitigate the recently growing CO problem from (formic acid and H2, CO) have been observed by HPLC,

2

some unavoidable CO sources (steel plants, thermal power NMR and GC.Till yet, the selective conversion of CO

2

2

plants and industries). For this work, CuO nanowires and Bi to formic acid is the target reached with the enhanced

nanocatalysts and their heterostructures were fabricated Faradaic efficiency (38-40%). Our futuristic improvements

on Cu foam and carbon paper and eCO R has been studied include a proper choice of the electrolyzers, membranes,

2

by home-made H-type and flow CO electrolyzers. The and electrocatalysts to meet the target proposed by the

2

process has been optimized against the prepared catalysts techno-economic analyses.

44 ANNUAL REPORT 2021-22