Page 17 - Annual Report_21-22

P. 17

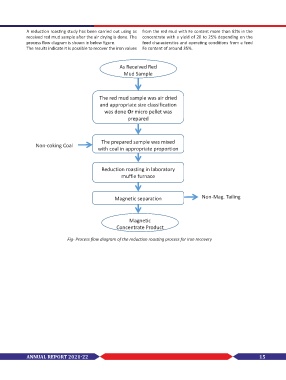

A reduction roasting study has been carried out using as from the red mud with Fe content more than 62% in the

received red mud sample after the air drying is done. The concentrate with a yield of 20 to 25% depending on the

process flow diagram is shown in below figure. feed characterstics and operating conditions from a feed

Reduction roasting study has been carried out using as received red mud sample after the air

The results indicate it is possible to recover the iron values Fe content of around 35%.

drying is done. The process flow diagram is shown in below figure 1.

As Received Red

Mud Sample

The red mud sample was air dried

and appropriate size classification

was done Or micro pellet was

prepared

The prepared sample was mixed

Non-coking Coal

with coal in appropriate proportion

Reduction roasting in laboratory

muffle furnace

Magnetic separation Non-Mag. Tailing

Magnetic

Concentrate Product

Fig- Process flow diagram of the reduction roasting process for iron recovery

Figure 1: Process flow diagram of the reduction roasting process for iron recovery

The results indicate it is possible to recover the iron values from the red mud with Fe content

more than 62% in the concentrate with a yield of 20 to 25% depending on the feed

characterises and operating conditions from a feed Fe content of around 35%.

Beneficiation study for recovery of manganese value from mixed manganese metal

waste generated at FAP Joda

Sponsored by: M/s. Tata Steel Limited

Ferro-manganese plant generates number of solid wastes. The mixed metal-slag is one such

waste generated in the plant. After removal of pure metal and pure slag there exists a mixture

of slag and metal at the slag-metal interface. These mixed metal-slag need to be processed for

recovering the manganese metal values. The mixed metal-slag contains substantial amount of

manganese values in it. There is a huge potential to recover these values for value addition

and ultimately improving the productivity of the plant. M/s. Tata Steel Limited is interested

ANNUAL REPORT 2021-22 15

in recovering manganese values from the slag using beneficiation methods.