Page 20 - Annual Report_21-22

P. 20

Studies on the characterisation and beneficiation of tensa iron ore fines to develop an iron ore

process flowsheet

To envisage national steel production of 300 million tons In this regard, M/s. JSPL Anugul has approached CSIR-

by 2030, M/s. JSPL, Ltd. put up a 6000 MTPA integrated IMMT to develop a beneficiation process for iron ore fines

steel plant at Anugul, Odisha, India. Presently, the plant to improve the grade of the ore and reduce the alumina

is receiving a part of iron ore used in steelmaking as fines content of the ore. Different process flowsheets have been

from Tensa mines, Odisha. The average composition of developed following physical beneficiation and reduction

iron ore fines is 57% Fe, 9.23% SiO , 4.6% Al O and 3.47% roasting. It is possible to upgrade the ore to 64.5% with a

2

2

3

LOI. The present grade is not suitable for steel making and 79% yield.

requires to beneficiate improving it into a steel grade ore.

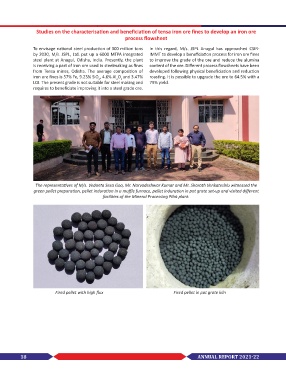

The representatives of M/s. Vedanta Sesa Goa, Mr. Narvadeshwar Kumar and Mr. Sharath Venkateshlu witnessed the

green pellet preparation, pellet induration in a muffle furnace, pellet induration in pot grate set-up and visited different

facilities of the Mineral Processing Pilot plant.

Fired pellet with high flux Fired pellet in pot grate kiln

18 ANNUAL REPORT 2021-22