Page 18 - Annual Report_21-22

P. 18

Beneficiation study for the recovery of manganese value from mixed manganese metal waste

generated at FAP Joda

The Ferro-manganese plant generates a number of solid plant. M/s. Tata Steel Limited is interested in recovering

wastes. The mixed metal-slag is one such waste generated manganese values from the slag using beneficiation

in the plant. After the removal of pure metal and pure slag methods.

there exists a mixture of slag and metal at the slag-metal The feed material contains the Mn value in the range of

interface. These mixed metal-slag need to be processed to 25 to 29%. The process has been developed using physical

recover the manganese metal values. The mixed metal-slag beneficiation techniques to enrich the manganese value

contains a substantial amount of manganese values in it. in the concentrate. The results indicate that the processed

There is a huge potential to recover these values for value developed could enrich the manganese content to more

addition and ultimately improving the productivity of the than 40% in the concentrate.

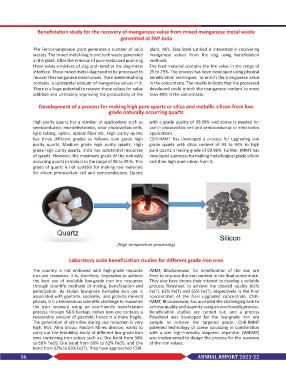

Development of a process for making high pure quartz or silica and metallic silicon from low

grade naturally occurring quartz

High purity quartz has a number of applications such as with a grade quality of 99.99% and above is needed for

semiconductor, microelectronics, solar photovoltaic cells, use in photovoltaic cell and semiconductor or electronics

light tubing, optics, optical fiber etc. High purity quartz applications.

has three different grades as follows: Low grade high CSIR-IMMT has developed a process for upgrading low

purity quartz, Medium grade high purity quartz, High grade quartz with silica content of 93 to 94% to high

grade high purity quartz, India has substantial resources pure quartz a having grade of 99.96%. Further, IMMT has

of quartz. However, the maximum grade of the naturally developed a process for making metallurgical grade silicon

occurring quartz in India is in the range of 98 to 99 %. This and then high pure silicon from it.

grade of quartz is not suitable for making raw materials

for silicon photovoltaic cell and semiconductors. Quartz

(High temperature processing)

Laboratory scale beneficiation studies for different grade iron ores

The country is not endowed with high-grade requisite IMMT, Bhubaneswar, for beneficiation of the iron ore

iron ore resources. It is, therefore, imperative to achieve fines to improve the iron content in the final concentrate.

the best use of available low-grade iron ore resources They also have shown their interest to develop a suitable

through scientific methods of mining, beneficiation and process flowsheet to achieve the desired quality (62%

pelletization. As Indian low-grade hematite iron ore is Fe(T), 63% Fe(T) and 65% Fe(T), respectively in the final

associated with goethite, kaolinite, and gibbsite mineral concentrate) of the final upgraded concentrate. CSIR-

phases, it is a tremendous scientific challenge to maximize IMMT, Bhubaneswar, has accepted the challenging task to

the iron recovery using an eco-friendly beneficiation achieve quality and quantity using an eco-friendly process.

process through R&D backup. Indian iron ore contains a Beneficiation studies are carried out, and a process

reasonable amount of goethite; hence it is more fragile. flowsheet was developed for the low-grade iron ore

The generation of ultra-fine during size reduction is very sample to achieve the targeted grade. CSIR-IMMT

high. M/s. Atha Group, Roida-II Mines division, wants to patented technology of screw scrubbing in combination

carry out the feasibility study of different low-grade iron with a wet high-intensity magnetic separator (WHIMS)

ores containing iron values such as; Ore band from 58% was implemented to design the process for the recovery

to 60% Fe(T), Ore band from 60% to 62% Fe(T), and Ore of the iron values.

band from 62% to 63% Fe(T). They have approached CSIR-

16 ANNUAL REPORT 2021-22