Page 67 - Annual Report_21-22

P. 67

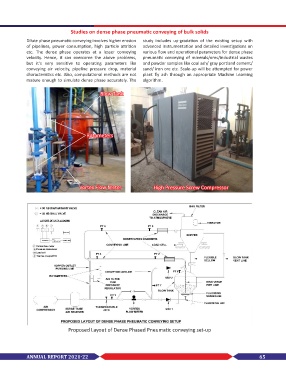

Studies on dense phase pneumatic conveying of bulk solids

Dilute phase pneumatic conveying involves higher erosion study includes up-gradation of the existing setup with

of pipelines, power consumption, high particle attrition advanced instrumentation and detailed investigations on

etc. The dense phase operates at a lesser conveying various flow and operational parameters for dense phase

velocity. Hence, it can overcome the above problems, pneumatic conveying of minerals/ores/industrial wastes

but it’s very sensitive to operating parameters like and powder samples like coal ash/ gray portland cement/

conveying air velocity, pipeline pressure drop, material sand/ iron ore etc. Scale-up will be attempted for power

characteristics etc. Also, computational methods are not plant fly ash through an appropriate Machine Learning

mature enough to simulate dense phase accurately. The algorithm.

Blow Tank

Rotameters

Vortex Flow Meter High Pressure Screw Compressor

Proposed Layout of Dense Phased Pneumatic conveying set-up

ANNUAL REPORT 2021-22 65