Page 70 - Annual Report_21-22

P. 70

ENVIRONMENT & SUSTAINABILITY

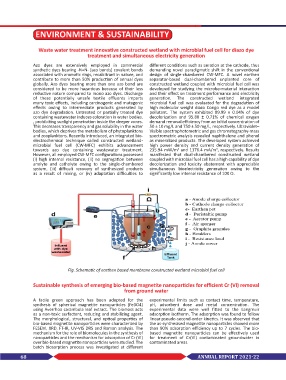

Waste water treatment innovative constructed wetland with microbial fuel cell for diazo dye

treatment and simultaneous electricity generation

Azo dyes are extensively employed in commercial different conditions such as aeration at the cathode, thus

synthetic dyes bearing -N=N- (azo bonds) covalent bonds demanding novel paradigmatic shift in the conventional

associated with aromatic rings, recalcitrant in nature, and design of single-chambered CW-MFC. A novel earthen

contribute to more than 50% production of annual dyes separator-based dual-chambered unplanted core of

globally. Azo dyes bearing more than one azo bond are constructed wetland coupled with microbial fuel cell was

considered to be more hazardous because of their less developed for studying the microbe-material interaction

reductive nature compared to mono azo dyes. Discharge and their effect on treatment performance and electricity

of these potentially unsafe textile effluents imparts generation. The constructed wetland integrated

many toxic effects, including carcinogenic and mutagenic microbial fuel cell was evaluated for the degradation of

effects owing to intermediate products generated by high molecular weight diazo Congo red dye as a model

azo dye degradation. Untreated or partially treated dye pollutant. The system exhibited 89.99 ± 0.04% of dye

containing wastewater induces coloration in water bodies, decolorization and 95.80 ± 0.71% of chemical oxygen

, prohibiting sunlight penetration inside the deeper zones. demand removal efficiency from an initial concentration of

This decreases transparency and gas solubility in the water 50 ± 10 mg/L and 750 ± 50 mg/L, respectively. Ultraviolet–

bodies, which deprives the metabolism of phytoplanktons Visible spectrophotometric and gas chromatography-mass

and zooplanktons. Recently introduced, an integrated bio- spectrometric analysis revealed naphthalene and phenol

electrochemical technique called constructed wetland- as mineralized products. The developed system achieved

microbial fuel cell (CW-MFC) exhibits advancement high power density and current density generation of

towards azo dye containing wastewater treatment. 235.94 mW/m and 1176.4 mA/m , respectively. Results

3

3

However, all employed CW-MFC configurations possessed manifested that dual-chambered constructed wetland

(i) high internal resistance, (ii) no segregation between coupled with microbial fuel cell has a high capability of dye

anolyte and catholyte owing to the single-chambered decolorization and toxicity abatement with appreciable

system, (iii) difficult recovery of synthesized products simultaneous bioelectricity generation owing to the

as a result of mixing, or (iv) adaptation difficulties to significantly low internal resistance of 100 Ω.

Fig. Schematic of earthen based membrane constructed wetland microbial fuel cell

Sustainable synthesis of emerging bio-based magnetite nanoparticles for efficient Cr (VI) removal

from ground water

A facile green approach has been adopted for the experimental limits such as contact time, temperature,

synthesis of spherical magnetite nanoparticles (Fe3O4) pH, adsorbent dose and metal concentration. The

using Averrhoa carambola leaf extract. The biomass acts experimental data were well fitted to the Langmuir

as a non-toxic surfactant, reducing and stabilizing agent. adsorption isotherm. The adsorption was found to follow

The morphological, structural, and optical properties of linear pseudo-second-order kinetics. It was observed that

bio-based magnetite nanoparticles were characterized by the as-synthesised magnetite nanoparticles showed more

FESEM, XRD, FT-IR, UV-VIS DRS and Raman analysis. The than 90% adsorption efficiency up to 7 cycles. The bio-

mechanism for the role of biomolecules in the synthesis of based magnetite nanoparticles can be effectively used

nanoparticles and the mechanism for adsorption of Cr (VI) for treatment of Cr(VI) contaminated groundwater in

over bio-based magnetite nanoparticles were studied. The contaminated areas.

batch biosorption process was investigated at different

68 ANNUAL REPORT 2021-22