Page 31 - Annual Report_21-22

P. 31

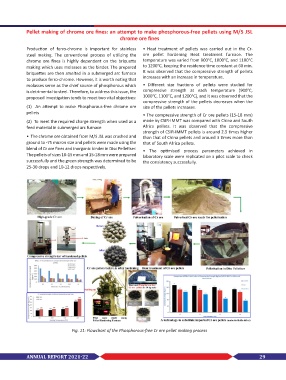

Pellet making of chrome ore fines: an attempt to make phosphorous-free pellets using M/S JSL

chrome ore fines

Production of ferro-chrome is important for stainless • Heat treatment of pellets was carried out in the Cr-

steel making. The conventional process of utilizing the ore pellet hardening Heat treatment furnace. The

chrome ore fines is highly dependent on the briquette temperature was varied from 900°C, 1000°C, and 1100°C

making which uses molasses as the binder. The prepared to 1200°C, keeping the residence time constant at 60 min.

briquettes are then smelted in a submerged arc furnace It was observed that the compressive strength of pellets

to produce ferro-chrome. However, it is worth noting that increases with an increase in temperature.

molasses serve as the chief source of phosphorous which • Different size fractions of pellets were studied for

is detrimental to steel. Therefore, to address this issue, the compressive strength at each temperature (900°C,

proposed investigation tends to meet two vital objectives: 1000°C, 1100°C, and 1200°C), and it was observed that the

compressive strength of the pellets decreases when the

(1) An attempt to make Phosphorous-free chrome ore size of the pellets increases.

pellets • The compressive strength of Cr ore pellets (15-18 mm)

(2) To meet the required charge strength when used as a made by CSIR-IMMT was compared with China and South

feed material in submerged arc furnace Africa pellets. It was observed that the compressive

strength of CSIR-IMMT pellets is around 2.5 times higher

• The chrome ore obtained from M/S JSL was crushed and than that of China pellets and around 3 times more than

ground to -75 micron size and pellets were made using the that of South Africa pellets.

blend of Cr ore fines and inorganic binder in Disc Pelletiser. • The optimised process parameters achieved in

The pellets of sizes 10-15 mm and 15-18 mm were prepared laboratory scale were replicated on a pilot scale to check

successfully and the green strength was determined to be the consistency successfully.

25-30 drops and 10-12 drops respectively.

Fig. 11: Flowchart of the Phosphorous-free Cr ore pellet making process

ANNUAL REPORT 2021-22 29