Page 32 - Annual Report_21-22

P. 32

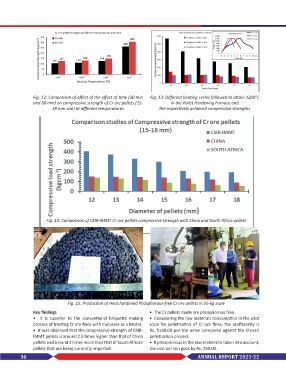

Fig. 12: Comparison of effect of the effect of time (30 min Fig. 13: Different heating cycles followed to attain 1200°C

and 60 min) on compressive strength of Cr ore pellets (15- in the Pellet Hardening Furnace and

18 mm size) at different temperatures the respectively achieved compressive strengths

Fig. 14: Comparison of CSIR-IMMT Cr ore pellets compressive strength with China and South Africa pellets

Fig. 15: Production of Heat hardened Phosphorous-free Cr ore pellets in 55-kg scale

Key findings • The Cr pellets made are phosphorous free.

• It is superior to the conventional briquette making • Considering the raw materials consumption in the pilot

process of treating Cr ore fines with molasses as a binder. scale for pelletisation of Cr ore fines, the profitability is

• It was observed that the compressive strength of CSIR- Rs. 5160.00 per ton when compared against the China’s

IMMT pellets is around 2.5 times higher than that of China pelletisation process.

pellets and around 3 times more than that of South African • If phosphorous in the raw material is taken into account,

pellets that are being currently imported. the cost per ton goes by Rs. 250.00.

30 ANNUAL REPORT 2021-22