Page 33 - Annual Report_21-22

P. 33

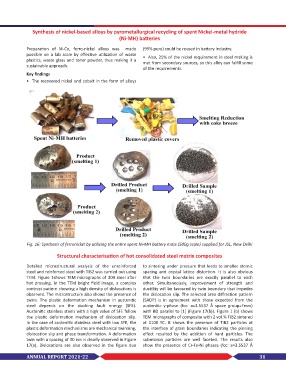

Synthesis of nickel-based alloys by pyrometallurgical recycling of spent Nickel-metal hydride

(Ni-MH) batteries

Preparation of Ni-Co, ferro-nickel alloys was made (99% pure) could be reused in battery industry.

possible on a lab scale by effective utilization of waste • Also, 25% of the nickel requirement in steel making is

plastics, waste glass and toner powder, thus making it a met from secondary sources, so this alloy can fulfill some

sustainable approach.

of the requirements.

Key findings

• The recovered nickel and cobalt in the form of alloys

Fig. 16: Synthesis of ferronickel by utilizing the entire spent Ni-MH battery mass (500g scale) supplied for JSL, New Delhi

Structural characterisation of hot consolidated steel matrix composites

Detailed microstructural analysis of the unreinforced to sintering under pressure that leads to smaller atomic

steel and reinforced steel with TiB2 was carried out using spacing and crystal lattice distortion. It is also obvious

TEM. Figure 1shows TEM micrographs of 304 steel after that the twin boundaries are exactly parallel to each

hot pressing. In the TEM bright field image, a complex other. Simultaneously, improvement of strength and

contrast pattern showing a high density of dislocations is ductility will be favoured by twin boundary that impedes

observed. The microstructure also shows the presence of the dislocation slip. The selected area diffraction pattern

twins. The plastic deformation mechanism in austenitic (SADP) is in agreement with those expected from the

steel depends on the stacking fault energy (SFE). austenitic γ-phase (fcc: a=3.5537 Å space group=Fmm)

Austenitic stainless steels with a high value of SFE follow with BD parallel to [1] (Figure 17(b)). Figure 1 (b) shows

the plastic deformation mechanism of dislocation slip. TEM micrographs of composite with 2 vol.% TiB2 sintered

In the case of austenitic stainless steel with low SFE, the at 1100 ºC. It shows the presence of TiB2 particles at

plastic deformation mechanisms are mechanical twinning, the interface of grain boundaries indicating the pinning

dislocation slip and phase transformation. A deformation effect resulted by the addition of hard particles. The

twin with a spacing of 30 nm is clearly observed in Figure submicron particles are well faceted. The results also

17(a). Dislocations are also observed in the figure due show the presence of Cr-Fe-Ni phases (fcc: a=3.5537 Å

ANNUAL REPORT 2021-22 31